|

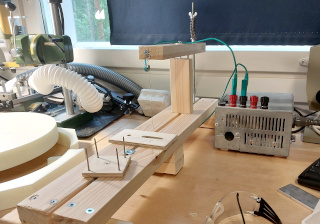

The power supply: I used the same power supply through all iterations

of the hot wire cutter. A simple toroidal transformer that outputs 24 VAC

with certainly more than enough current capacity (I don't actually remember

what I got this transformer for, originally) fed by a Lübcke Vario

R52-260-T Variac which I've had in my

electronics lab for quite a while, since rescuing it from a dumpster at

my old university.

This is by no means a sensible way to power a hot wire cutter, but it was

immediately available, and works just fine. I usually set the variac to

about 30 V output (giving just over 1 V from the following

transformer), but that will depend on the thickness of the wire

in the cutter. Mine is probably on the thick side, as far as hot wires go.

Some kind of low-voltage high-current SMPS should not be too difficult to

design, if you don't have a variac on hand. Or I wonder if an old-school light

dimmer might work in place of the variac.

|

|

The first generation cutter: This was made of particle board

scraps and a clothes pin, clued together! Cobbled together in 10 minutes

or so. But the wire was some "actual"

resistance wire, for whatever that's worth... Rather thick, though, so

it required some serious current at low voltage. Of course, any uninsulated

wire would do, regardless whether it's Nichrome or Kanthal or plain old

iron or steel (well, maybe not copper, though).

The wire is contacted electrically by alligator clips, placed between the

physical connection points, so as not to needlessly heat those up—the

plastic clothes pin, used to keep tension on the wire, would soon melt

otherwise!

You can see the jaw is not terribly big, and there's precisely nothing at

all to adjust. I mostly used it for cutting

freehand, or clamped some simple

guide rail onto this thing if I needed uniform, straight pieces of foam core.

|

|

The second generation cutter: Having misplaced the first cutter,

and finding myself needing one again, I jury rigged this one in about the

same time as before, again of materials immediately on hand. This one has

a slightly larger jaw, but in most other respects it's only marginally less

awful than the original. Still sporting the clothes pin and alligator clips.

I did connect the lower end of the wire to a moveable block underneath the

base board. With the sizeable hole in the base board, this allowed me to fine

tune the wire to make it actually vertical with some accuracy. Nothing holds

that lower block in place, though (other than the tension on the wire, and

friction against the base board), so it's also prone to losing its fine

adjusted vertical setting.

|

|

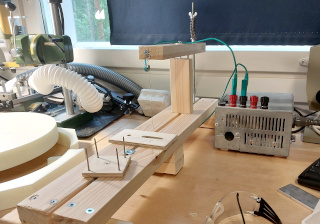

The third generation cutter: I found myself needing rings cut out of

EPS ("Finnfoam"), so I finally went to the trouble of actually

designing a hot wire cutter for that purpose. (The same cutter will,

of course, work just as well for freehand and straight pieces as the earlier

two generations.)

I think the photo

(and the following photos) says it all. There are two lengths of wood with

a gap between them. An axle piece with four nails sticking up from it is

pushed into the EPS sheet, and it provides a pivot point around which the

sheet can be turned through the wire to make accurate circles (see

this photo).

That axle can move back and forth along the gap

between the wooden pieces, and adjustable stoppers in the groove are used

to set the radius of the circle. This way I can heat up the wire, push the

raw EPS sheet into the wire until I hit the stopper, turn the circle

(as in this photo), and

pull it out again—this leaves no unsightly grooves at the starting point

of the circular cut. I can also start from a pre-drilled hole on the

inside of the disc, pull the raw sheet backwards to the pre-set

radius, turn the inner circle, and push out again, to obtain a ring

of EPS. (Of course this does

require disconnecting the wire and threading it through that pre-drilled

hole, and disconnecting it again after cutting.)

The jaw is bigger than in the earlier versions, and comprises a vertical

block of wood, on which a horizontal beam is hinged, and tensioned by an

adjustable compression spring, as you can see in

this photo. The hinge

is nothing more than two round-headed screws protruding from the vertical

block, sitting in holes ground into the horizontal beam. The single screw

and washer you can see in the photo only keeps the beam from falling off

when the wire is unhooked.

The lower

end of the wire is held by a moveable block (as in the second generation

cutter), and by changing its position, you can even cut conical

parts as in this photo.

(If the angle is off 90° by very much, that block will try to slide

back towards the 90° position, unless held by some makeshift cord

arrangement—that orange cord you see in the photo—adjusted by

adding or removing blocks of wood behind it. Not all too convenient, but

workable.)

And yes, the power supply

is still connected with alligator clips.

|