The full footprint sold by Hilleberg (which seems to cost some 140 eur!) is marketed as protecting the floor of the tent from wear and tear. I've heard rumors (unconfirmed, of course) of Hilleberg engineers themselves stating that the footprint is stupid—the floor of the tent is by far strong enough to survive normal use, and they only make the footprints because people request them regardless!

I do not use my wood-burning campstove in the tent vestibule, as that would be more of a fire hazard, and the smoke would stink up the tent big time.

In exceptionally fine weather, the vestibule of the Nallo 3 GT can be rolled back, effectively leaving the front of the tent open, with just a short "hood" above it (as detailed in the tent's instruction manual). To do that, I just need to detach the groundsheet from the two front corners, and fold part of the groundsheet underneath itself out of the way.

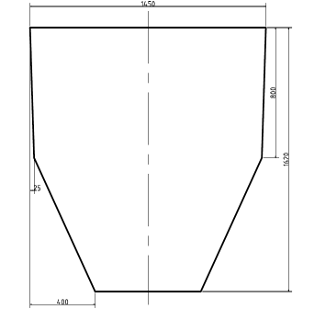

The width of the fabric initially, including frayed edges, was 155 cm. I sewed turned hems on all edges, which used up some of the total width—that's where the final maximum width of 145 cm came from. That left a gap of just over 10 cm to the outer tent wall on either side, so I maintained that same gap all around—that's where the rest of the final dimensions came from.

Elastic straps, made of some 5 mm wide elastic band just over 20 cm long per strap, extend as loops from each of the six corners of the groundsheet. The band passes through the toggle bead (an ITW Tactical toggle, no less, as I happened to have those in shelf—don't ask), and both ends of the band are sewn to the groundsheet inside the hem. Thus the bead is at slightly less than 10 cm distance from the edge of the fabric (again, not too critical). That places just a slight tension on the straps, so the groundsheet settles in place smoothly.

The cost was something like 20 eur total—and that's including the overpriced toggle beads.