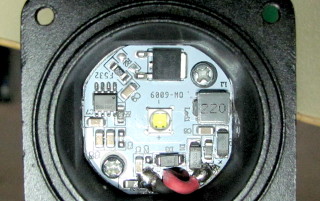

This lamp has four prominent Allen screws on the back of the housing, holding the lamp together. Once those were removed, the thing came apart easily (unlike some other LED lights, where the transparent plastic lens is glued onto the aluminum body). There are gaskets between the aluminum parts, the reflector and the lens, so the thing should be quite weatherproof despite the aluminum parts having a sizeable gap between them (wide enough to insert a piece of paper). Earlier I was considering sealing the gap with silicone caulk or something—not necessary!

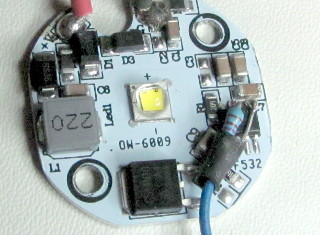

The datasheet, however, offered two better alternatives: (1) muck about with the reference voltage at the LD pin that the current sensing resistor is compared against (in this circuit, LD is tied to Vdd and the controller is thus using its own internal reference), or (2) feed a PWM signal into the controller's PWMD pin (essentially an "Enable" pin, which is also tied to Vdd in this circuit). The latter seemed less hassle, and also that pin, being more easily accessible in the corner of the SO8 package, would be easier to lift off the PCB.

Once the PCB was out, I lifted pin 5 (PWMD) of the controller chip from the PCB. I then soldered a 7.87 kΩ pull-up resistor between it and Vdd (pin 6). Anything slightly below 10 kΩ should do according to the datasheet, even under any worst-case tolerance combination. Directly to the PWMD pin I soldered a wire which, when grounded, will turn off the LED, whereas when left floating, the LED remains on. By feeding it with suitable PWM, I could dim the intensity, which is what I wanted. I put a piece of heat-shrink tubing around the "loose" end of the resistor. Note that PWMD should be pulled high only to Vdd (which is internally regulated by the chip), not to the supply voltage! Going too far above Vdd will exceed the specifications of the GM9910BG and likely break it. So you want to have the pull-up resistor here inside the lamp, and have the PWM circuit (described below) only pull it down to ground.

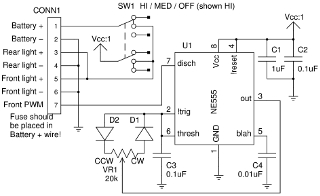

There is a 3-position "ON/ON/ON" double pole switch to select between HIGH, LOW and OFF. It switches the front light and the red rear light on and off, and in the middle position also activates the PWM circuit which dims the front light (see the schematic for the switch configuration). When the PWM circuit is unpowered, the LED shines at full intensity. Alternatively, I could have made the front light continuously adjustable by the potentiometer, but I really just wanted HIGH and LOW beams.

I reassembled the lamp housing, taking the PWM wire outside through the same hole used by the supply lead (which I had to replace, since I had just cut the original one). Not to fall short of the original weatherproofing, I also filled the back of the housing with epoxy like before, then reinstalled the aluminum-core PCB with new thermal grease (the PCB acts as a heat conductor from the LED to the housing).

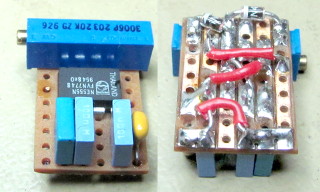

A couple of wire connections are made out in the open, but properly sealed with hot-melt glue and heat-shrink tubing. Cable ties keep the wiring in place along the bike's frame. I used Powerpole connectors for the battery—these are not waterproof, but I try to keep them out of direct rain. A slow-blow 2 A fuse is in the power cord coming from the battery. The battery also has a 5-pole JST XH balancer connector.

The LiFePO4 battery pack sits in a waterproofed Cordura fabric pouch attached to the handlebars. It is self-made, and waterproofed with a mixture of approximately 1:1 (by weight) of transparent sanitary silicone sealant and lamp kerosene (yes, really). These can be weighed into a jar and mixed by shaking for some minutes. The resulting goop can be simply painted onto the fabric with a brush and left to dry and set for a couple of days. While wet, the goop stinks to high hell, though—much worse than the silicone sealant alone!

However, stuff those flashing headlights somewhere where the Sun don't shine! You do not need that much extra visibility! Have you ever considered how much fun it would be, if everyone used flashing headlights??? Including cars??? Flashing lights should be for turn signals, emergency vehicles and warning signs only! So don't even think of decreasing the 555's frequency down to 4 Hz, or the ghost of Baron Karl von Drais will come to haunt you in the night!