|

So after a few years' hiatus from portable ops, I finally decided to build

an external battery pack using low

self-discharge NiMH D cells made by Ansmann under the

brand name "Max-E". These cells provide

8 500 mAh of capacity (which I verified individually

before soldering them together, and they do come very, very close) and

have no problem with the 3 or 4 amps that the FT-897 maxes at

when transmitting SSB at 20 W output (the consumer D cell is rated

for 8.5 A continuous discharge according to the datasheet, the

industrial version much higher still).

They are sold in blister packs of two cells each, so six packs are needed

for the 11-cell (13.2 V) configuration used in the FNB-78, with one

cell left over. Since I'll be making another 11-cell pack also, that odd cell

won't go to waste.

These 34 mm diameter cells do not, however, fit inside the battery

compartment of the FT-897, which is only some 26 mm high. Other

DIYers have fitted their

FT-897s with a new battery compartment

cover that extends outwards from the bottom, making room for the fatter

cells. I decided instead to forgo the convenience of internal batteries,

and make an external pack. After all, that could be used to power other

devices as well, so it also has its advantages. But I do sorely miss the

internal batteries... :(

|

|

After verifying their capacity,

I glued the cells together with hot glue, just to keep them in formation

while I solder them. One of the biggest limitations of hot glue is its

tendency to melt in high heat (well, duh), but I figured the cells should

not get really hot in my use (i.e. nowhere near the 120°C

that is often quoted as the melting temperature of hot glue, though it does

soften already much below that), and I'd be wrapping the whole thing in

heat-shrink tubing anyway (being careful not to melt the glue in the

process, and especially not to destroy the thermal fuse I

installed).

Hot glue is not 100% permanent (I consider that an advantage here),

i.e. they can be torn or cut apart after gluing, but regardless,

I did draw a diagram of the orientation of each cell, and how I

intend to connect the cells, the terminal wires, and the thermal fuse

together. I checked and re-checked this diagram before beginning the

assembly process, and checked and re-checked again

before gluing each cell. And I kept checking it while

soldering (see below), just to be sure. And hey, I got it right

the first time, so it all paid off! :)

|

|

Next I soldered the cells in series. For the interconnects, I used

8 mm wide nickel strip that I ordered from

eBay. With a touch of good quality

flux, I first pre-tinned both the battery terminals and the strip,

and then just melted them together. I used my 80 Watt

Weller WD-1000T

soldering station with a very wide 4.6 mm LT-D tip, set at a

rather high 380°C temperature, in order to melt the solder as fast as

possible. A lower temperature, a narrow tip, or an underpowered soldering

iron would require more heating time, actually allowing more heat to

flow into the cell. Heat

damages the cells very easily, and various sources on the Net tell you

not to solder to NiMH cells, but to use spot welding instead.

(In fact, that's the purpose this nickel strip is intended for, not soldering.)

A DIY spot welder should not be too difficult to make, but the videos I've

seen on Youtube don't really make it look all that gentle either. Anyway,

my cells survived soldering just fine.

For safety, I inserted a 72°C thermal fuse (the thing with the yellow

wires in the photo, enclosed in black heat shrink tube) in the space between

the middle three cells of the pack. It is only meant to break the circuit in

case the charger goes berserk and starts to overcharge the battery pack

for hours on end. I chose a 72°C fuse because that was the

lowest temperature available—it's still high enough to allow

charging the batteries with reasonable currents. I crimped the wires to the

fuse, enclosed it in heat-shrink tubing (which I shrunk only at the ends

to avoid damaging the fuse) and soldered the wires in series with the cells.

|

|

The 11-cell packs (I first made one for testing, then another identical one)

were enclosed in PVC heat-shrink tubing, which can be shrunk with an

ordinary hairdryer. (Many commercial battery packs as well as lithium

polymer batteries are enclosed in the same type of material.) Since it does

not require extreme heat to shrink, it is safe for the cells, as well as

the hot glue keeping them together, and the thermal fuse amidst the

cells. But it did turn out ugly as hell.

The battery packs' terminal wires were soldered directly to the cells,

and 2-pin Molex connectors were attached for good measure. I could just

as well have wired them directly to the rest of the circuit

(see below), but a connector seemed appropriate in case I need to remove

or replace a pack. I could have used

Powerpole

connectors here also, but somehow I never considered them for this kind of

internal connections. Damn. I did, of course, use Powerpoles for the

external connectors of the battery box, but there's really

no reason not to use them internally as well.

|

|

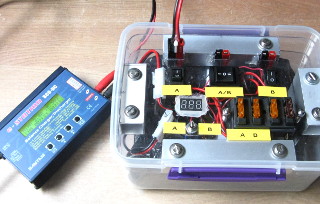

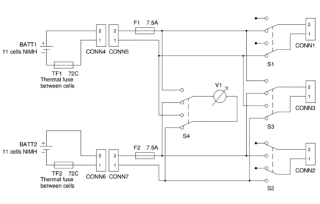

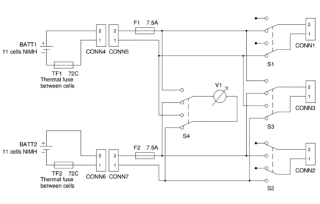

The two 11-cell battery packs are wired to three

Powerpole

connectors according to this wiring

diagram. Each battery has a dedicated connector with its

own on/off switch, and there is also a shared connector that can connect

to either battery via a third on/off/on 3-position switch. This allows:

- two packs to be used completely independently,

- one pack to be in use while the other is charging,

- two loads to be connected to a single pack without needing

a splitter cable, and

- immediate switching of the radio from one battery pack to

another with a single switch.

That last feature is the most important in practice, and does what the

"A/B" switch on the radio does for internal

batteries. A single returning (on)/off/(on) switch wired to a cheap

2-wire volt meter ordered from eBay allows checking the voltage of either

pack at any time (although the FT-897 also shows the battery voltage on its

display at all times).

All switches are two-pole,

so they isolate both the positive and negative side of the pack. In some

chargers, e.g. my

Bantam e-Station BC6-DC,

the negative output lead is not at ground potential, which would cause a

fuse to blow if the pack's negative side was grounded via the radio. The

two-pole switches mitigate that problem entirely. Also, they enable

connecting the packs in series, in case a 24 V portable supply is ever

needed. Finally, each battery pack has its own 7.5 A automotive-type

blade fuse. The fuses are held in a four fuse holder, which

leaves two unused slots to keep spare fuses in, which is nice.

|

|

The packs are housed in a plastic food storage box with a lid that can

be locked in place. I fitted two horizontal dividing walls inside. The

upper one has all the connectors and switches installed on it (as

detailted in the schematic

above), while the lower one provides a smooth

surface against the battery packs, which are housed in the lower part

of the box.

The bodies of the connectors and switches, as well as all the wiring,

are in the space between the walls, which are separated by spacers made

of 25 mm square aluminum tubing. The original lid of the box

still fits on top for transport, in order to keep dirt out of the connectors

and to prevent the switches from turning on inadvertently.

The fuses are accessible with the lid open,

in case they need replacement.

The whole thing weighs about 4 kg (about the same as a 12 V

12 Ah lead-acid).

The box and the dividing walls are both translucent or transparent plastic

for no good reason, which makes all the uglyness inside visible to the whole

world. Whatever, as long as it works... Simply remove the lid, attach the

radio's power cable, flip a switch and start operating.

|

|

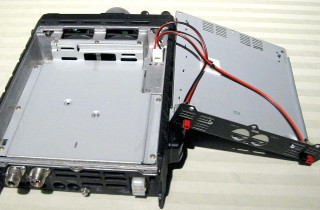

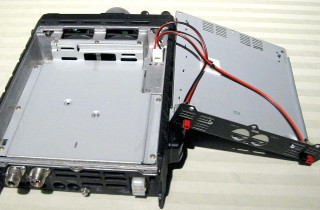

The FT-897 is designed to accommodate two internal battery packs, which

connect to two male 3-pole JST VH headers with 3.96 mm pitch

inside the radio (you can find compatible connectors on eBay—search

for "JST VH 3p 3.96"), and either one can be taken

into use with the "A/B" switch on the radio.

I wired both headers to separate Powerpole connectors which I mounted on

the back of the battery compartment cover with a makeshift arrangement

of aluminum profile, cable ties and hot glue.

Now I can connect my external battery pack to one, and another power

source (another battery, a car 12 V system, or an AC/DC adapter)

to the other, and select either one with the radio's

"A/B" switch.

The reason why I don't just wire the pack to the radio's external

13.8 VDC input is that when powered via the internal

connectors, the radio automatically limits its TX power to just

20 W, without needing to change the power setting through the menus.

And I definitely want the lower power when operating on batteries!

(Incidentally, the FT-857, which is like a smaller FT-897 without

provision for internal batteries, uses the extra pins on

its 13.8 VDC input connector to control its output power: if

pin 3 of the attached power supply cable is wired to GND, TX power

is automatically limited to 20 W. The FT-897 obviously does

not have this feature on its external power supply

connector, since there is physically no pin installed at the pin 3

position of the connector. Bummer.)

|

|

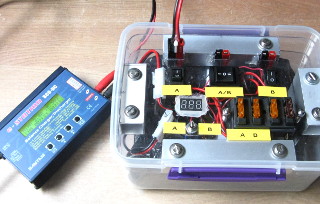

I use a

Bantam e-Station BC6-DC

to charge the batteries. It is a versatile multifunction charger that

can charge, discharge, balance and condition NiCd, NiMH, Li-ion, LiPo,

LiFe and SLA batteries of numerous cell counts at adjustable currents

up to 5 A. (The e-Station BC6 is the same thing with an internal

AC adapter, and the BC6-10 has a maximum charge current of 10 A;

otherwise I think they are the same.)

When charging NiMH batteries, it is advisable to

change the "NiMH Sensitivity D.Peak" setting in the

"USER SET PROGRAM" menu from "Default"

(8 mV/cell) to its minimum value of 5 mV/cell. Also, set

some reasonable values for "Capacity Cut-Off" (I use

10 000 mAh for this 8 500 mAh pack, and have

never had it cut off before completion) and maybe

"Safety timer" as well (at 2 A current I use

400 min, which is plenty).

For these 8 500 mAh cells even the

maximum current of the BC6-DC is less than 1C. The Ansmann Max-E

datasheet doesn't specify a

maximum charge current, but quotes charging times for

2.55 A (0.3C) and 4.25 A (0.5C) currents.

Since I'm usually not in a big hurry, I generally charge at just

2 A. That's about the same 0.25C that I like to use for my

2 000 mAh AA Eneloops when charging on my previous

TechnoLine/LaCrosse BC-900 charger (which eventually broke) or

my current SkyRC MC3000

charger. The AA Eneloops get hardly warm

at 500 mA current, whereas at 1000 mA they do heat up substantially

towards the end. Defaulting to only 500 mA, those have served me

for years on end. With any luck, and with

conservative charging, maybe these D-cell battery packs will as well. (But

with a single NiMH cell, the BC6-DC doesn't seem to reliably

detect the endpoint at 0.25C, and was inclined to overcharge—and

at the time I did not have my MC3000 yet. So while I

was testing the individual cells, I used 0.5C current i.e.

4 A, and the cells did become quite hot towards the end. Hot

enough to soften hot glue, in fact. But with the whole pack, the

BC6-DC terminates just fine at 2 A, and the pack hardly gets

warm at all.)

|

Of course, NiMH batteries should only be charged with a dedicated NiMH

charger. Don't try any other charger—not even your grandfather's old

RC hobby NiCd charger (although NiCd and NiMH have similar endpoint

detection, a NiCd charger is generally not sensitive enough to detect the

smaller negative delta V cutoff point of NiMH batteries). And never

charge any batteries unattended.

You have been warned.

I liked operating portable with my FT-897

with its internal FNB-78

battery packs, but those NiMH packs did not work well in my infrequent

use. When they finally died, I installed

lithium polymer batteries in their place. They

worked wonderfully, but I may have had a bad batch of cells, because they

puffed up after a very short period of very light use. I was left wishing

for a perfect battery chemistry that would have low self-discharge,

high capacity, low internal resistance and better behavior than those

RC model LiPo cells.

I liked operating portable with my FT-897

with its internal FNB-78

battery packs, but those NiMH packs did not work well in my infrequent

use. When they finally died, I installed

lithium polymer batteries in their place. They

worked wonderfully, but I may have had a bad batch of cells, because they

puffed up after a very short period of very light use. I was left wishing

for a perfect battery chemistry that would have low self-discharge,

high capacity, low internal resistance and better behavior than those

RC model LiPo cells.